The issue of biomass consumption in Denmark has garnered wall-to-wall coverage on Danish media over the past few days. The coverage gives an impression that all biomass comes from wood that has been cut from forests where the primary purpose is to supply wood for biomass production. However, this is far from accurate. Figures from NEPCon’s analysis show that a large part of biomass comes from residues from the timber industry and not directly from the forests.

NEPCon works with 76 wood pellet producers in 11 different countries with the aim to ensure that biomass production is conducted in accordance with international standards for responsible biomass production set by the Sustainable Biomass Program (SBP). According to their own data, these producers, who are all SBP certified, sold 4.5 million tonnes of biomass in the form of wood pellets in 2018 to, among other markets, Denmark.

We’ve collected the information from the producers on the type of materials they use to produce wood pellets. The figures show that manufacturers use mainly residual products such as sawdust and wood chips from sawmills and other wood industries for biomass production. In fact, this type of residual product accounts for as much as 61 percent of the material used by 76 manufacturers to produce wood pellets.

When tree trunks are processed in sawmills, roughly half of the volume usually turns into e.g. boards and other primary products, whereas the other half turns into sawdust, wood chips and other residual products. It is such residues that are made into pellets.

The remaining 39 percent of wood pellets are made from wood that comes directly from forests, for example in the form of thinning wood, branches, tree tops and tree trunks. When trees are felled, different parts of the trees, depending on their quality and dimension, can be used for different products. Those with smallest dimensions and poorest qualities such as branches, tree tops, etc., are used for biomass; thus biomass is often a residual product of what cannot be sold for more valuable purposes. Forest owners always try to sell wood at the highest price and the market will regulate what goes to biomass and what goes to other purposes e.g. furniture.

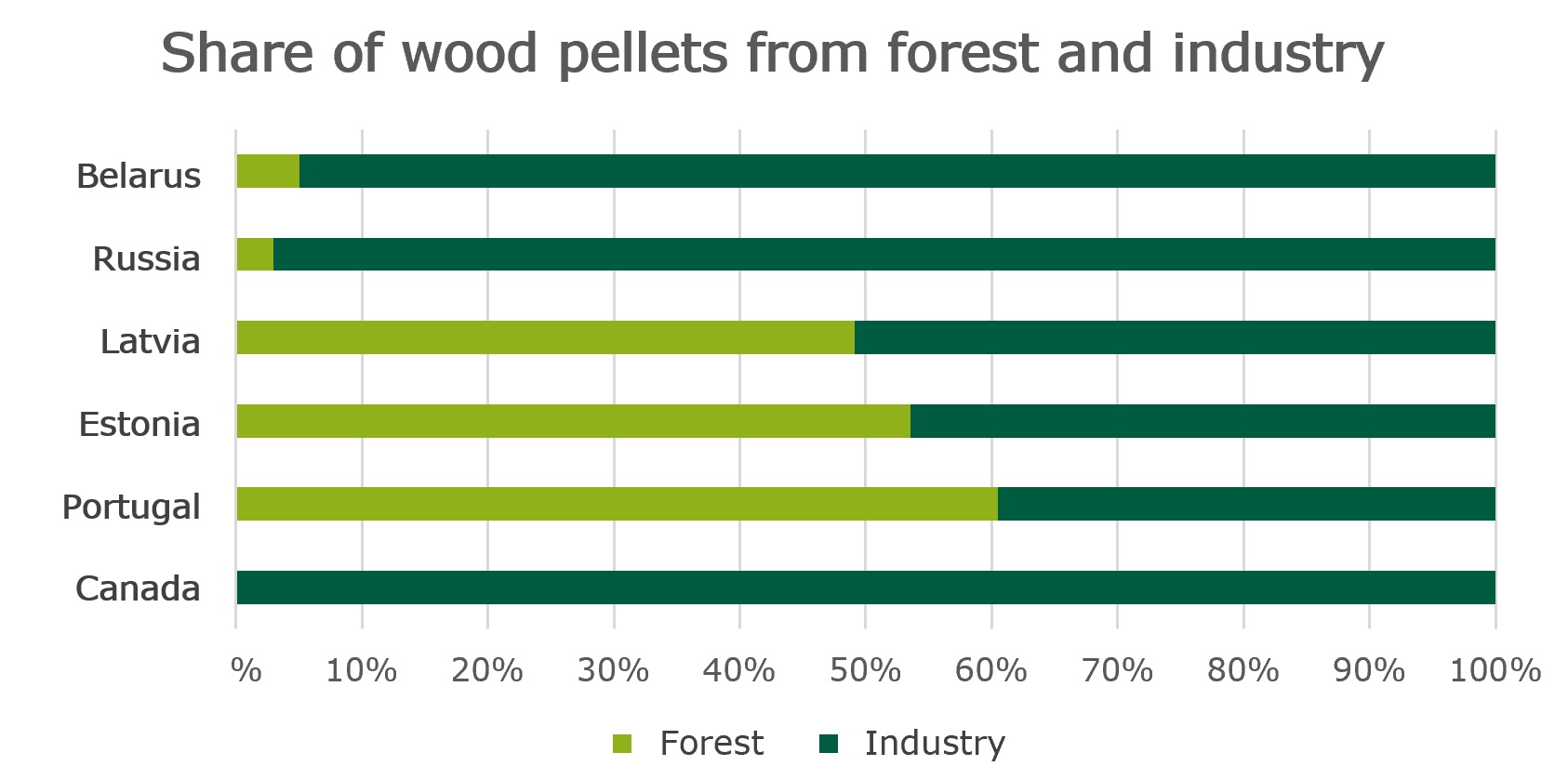

The figure below shows the distribution between wood from forests and industrial residues for the production of wood pellets in countries where we have data from at least 5 producers of wood pellets. We believe that this distribution reflects the distribution of input wood materials used in the production of wood pellets that Denmark imports from these countries.

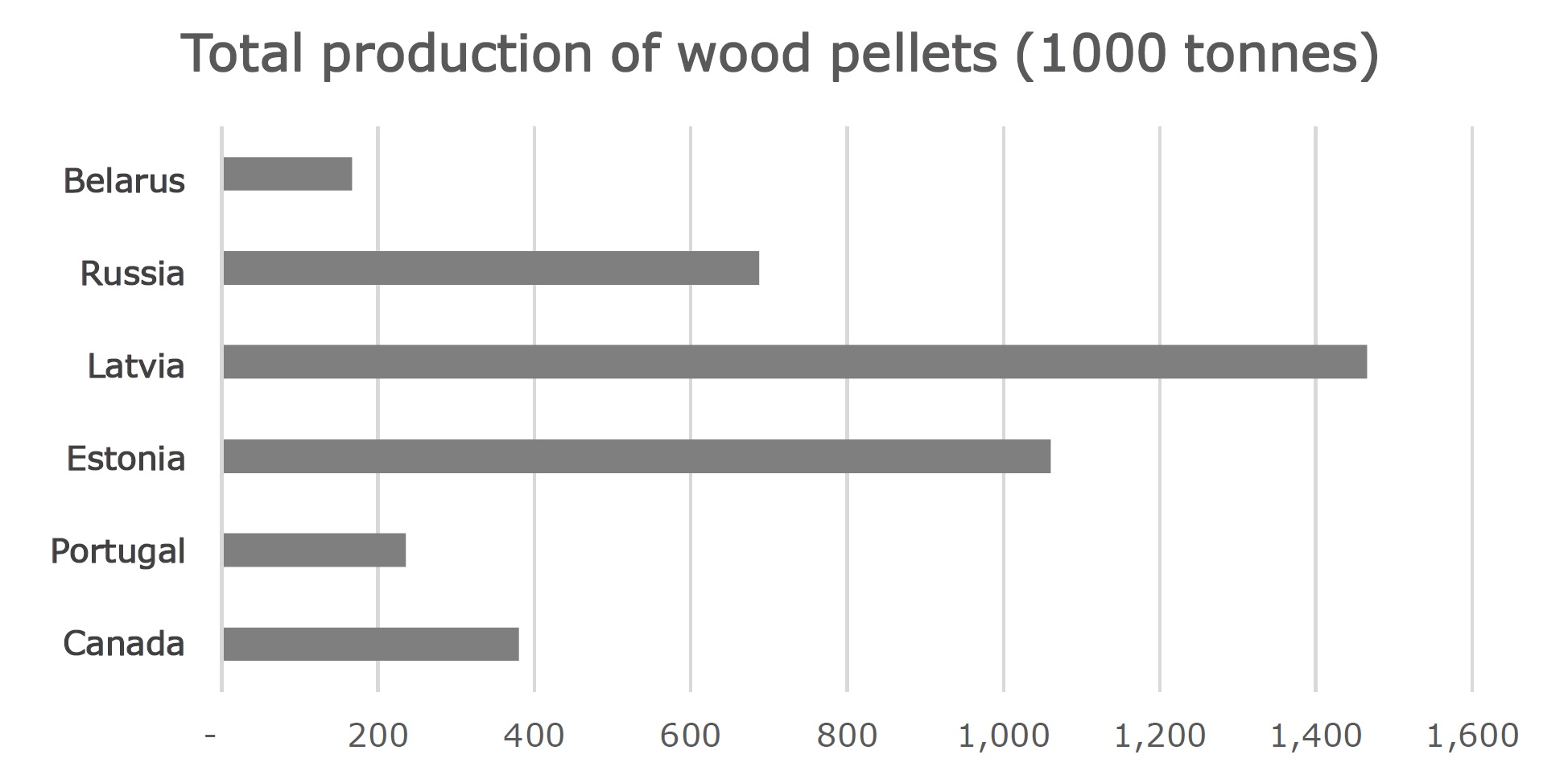

The following figure shows the total production of wood pellets from the same producers:

The current Danish media and some experts' description of the problem regarding the use of biomass is based on the assumption that it is exclusively wood that can be used for other types of wood products rather than biomass, such as structural wood, furniture, etc., is used to make wood pellets. However, the data NEPCon have analysed show that the vast majority of the wood used to produce wood pellets is from different types of residues from the timber processing industry.

It is important to take the above factual data into account in the current discussion in Denmark, as it confirms that the energy sector uses a large amount of residual wood for biomass.