Wine company, Vinicola s.r.o., is working to reduce carbon emissions from its products, which was kick-started by a devastating climate-induced event.

Vinicola s.r.o. is a family-run firm in Moravia in the Czech Republic that operates in the wholesale trade industry. The firm deals in wines from Chile, Argentina, Australia, New Zealand, the USA and other countries.

Own Moravian wines were first produced in 2010 with an annual production of 10,000 bottles and it now produces 520,000 bottles per year. The firm uses premium grapes from all over the Moravian wine-growing sub-regions to produce its fine wine. It also manages 40 hectares of its own vineyards.

Foreign and Moravian wines sold by Vinicola are delivered both to retail chains and directly to end customers.

A radical event

Located right in the Central Europe, the Czech Republic is prone to several climatic events and frequently faces floods, droughts and etc. In June 2021, a rare, violent, and deadly long-tracked tornado damaged several villages in the Hodonín and Břeclav districts of the South Moravian region of the Czech Republic. The devastating event made local people grew more concerned about the impacts of human activities on the planet as well as the future of the current and next generations after experiencing the consequences of climate change.

Seeing the unprecedented damage, the tornado left in the area, local people and businesses realised they must find ways to tackle these challenges without creating further harm to the planet.

The usage of fertilisers, pesticides, soil, land, water, energy and fuels results in around 20% of all greenhouse gas emissions. And winemaking is no exception. In general, the process of making wine generates carbon emissions that contribute to climate change globally.

As a result, Vinicola decided to take some substantial steps to reduce emissions from its production as well as come up with some solutions to make its products in a more climate-friendly manner. With the belief that changes start from within, they have started their journey and came up with the plan of creating footmarks for others to follow in their lead.

The company has started to identify and calculate its carbon footprint throughout the whole life cycle of wine production. On the other hand, looking at the increasing competition in the wine industry has also motivated them to take measures towards sustainable wine production, which can set them apart from their competitors.

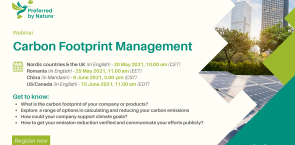

To accomplish this motion, Vinicola has utilised Preferred by Nature’s Carbon Footprint Management (CFM) certification as its guiding principle for improvement.

“The CFM certification is a one-stop solution for businesses of any size that want to communicate their efforts and progress towards the reduction of carbon emissions and achieve the company’s climate goals,” said Michal Rezek, Regional Manager for Strategic Development at Preferred by Nature.

Taking actions: Finding emission spots along the way

In April 2022, the company rolled up their sleeves to apply for the CFM certification for its products and adopted strategies on carbon reduction.

The breakdown of the company’s carbon footprint showed that 21% of its carbon emissions are made by glass bottles, 32% are related to fuels for tractors and company cars and some 15% were made while constructing the vineyard.

The rest of the emissions come from purchasing and transporting input materials (compost and organic fertilisers), transporting products, energy use, employee commuting, water consumption, waste production and so on.

For the base year of 2021, the final figure was 1.85 kgCO2e/ per 1 bottle (0,75l) of wine.

“Since the winery currently practices organic farming, it is unable to lower its carbon footprint by reducing the consumption of mineral fertilisers and pesticides. But the company must develop and release a climate policy and carbon footprint management plan, as well as pledge to reduce its carbon footprint by at least 4.2% per year, in order to obtain this certification,” added Michal.

The company’s products were evaluated against the Carbon Footprint Management Standard, calculating carbon footprints at various stages of wine production at the vinery. Land use change, raw material procurement and pre-processing, production, distribution and storage, and end-of-life are all included in the typical life cycle stages. Notably, the land-use change was not important in this case because all the grapes were grown in vineyards that were established on agricultural land more than 20 years ago.

The CFM standard requires companies to have a holistic approach to mitigate climate change by reducing the carbon footprint in the wine production life cycle. This includes every step from production, transport, storage, processing to consumption.

Wine production comes with both advantages and disadvantages at every stage, which requires deliberate action.

“In principle, the advantage of wine production is that it is an agricultural product and has several benefits when it comes to working in the vineyard,” said Karel Průša, Junior, Co-owner and Manager at Vinicola s.r.o.

“We also see great potential in the proper return of residual organic matter (waste from grapes and production) back to the soil. Mechanisation is an important component in wine production that can be purchased and has lower fuel consumption and environmentally friendly engines,” said Karel.

Wine is traditionally packaged in glass bottles, which is also its disadvantage when it comes to carbon reduction.

“Although glass is a recyclable material, repeated melting and production have a very negative effect on the carbon footprint,” explained Karel.

On the other hand, the company believes that optimising logistics efforts throughout the wine supply chain has enormous potential.

“Long-term distribution route reduction, storage and transport sharing efforts, as well as a shift to local suppliers of raw materials or from another vicinity, are all options we are working on,” explained Karel.

Certified, but continue the drive toward the net-zero target

To become carbon-neutral within the year 2025, the company aims to produce carbon-neutral products through carbon insetting and offsetting. As such, Vinicola intends to lower the carbon footprint of its products mainly by purchasing green electricity, reducing electricity consumption and having its own photovoltaics.

The company also plans for better logistics for grapes, compost and other inputs. In addition, they are seeking to change the bottle type to make it lighter as well as promote the use of carbon offsets to compensate for resting emissions.

“We plan to maximise the use of energy from renewable sources,” Karel further explained their plan.

A large part of the company’s carbon footprint is generated by the transport of grapes from vineyards to processing centres. To reduce this, “we have reconstructed an old production plant located right next to our vineyards. It would also be ideal if we could find suppliers of ingredients and materials who have also embarked on this journey,” said Karel.

Apart from these, Vinicola intends to invest in offset projects in the near future.

About the carbon standard

Preferred by Nature has taken over a decade to develop the CFM Support and Verification Programme to help any organisation seeking to implement credible and responsible climate actions.

The CFM standard is a one-stop solution that sets out steps for organisations that aspire to become carbon neutral and make credible and responsible claims about their activities.

The CFM Support and Verification Programme is aligned with internationally recognised standards, such as GHG Protocol, PAS standards and ISO 14064. Whether an organisation wants to systematically manage its carbon footprint, realise GHG reductions and targets, or navigate carbon offsetting options, the Standard offers the solutions.

“This CFM certification is a significant advantage to us and helps us gain an edge over the competition. It is also a credible demonstration for us to communicate with our customers about our climate-friendly products. I firmly believe that sooner or later these ideas will become a trend – in time, it could even become legislation,” added Karel.

For more information, please contact:

Michal Rezek

Regional Manager for Strategic Development in Central and Eastern Europe

[email protected]

Note: Cover photo courtesy of Vinicola s.r.o.